Power cables are cables used to transmit and distribute […]

Power cables are cables used to transmit and distribute electrical energy. Power cables are often used in urban underground power grids, power station outgoing lines, internal power supply in industrial and mining enterprises, and underwater transmission lines across the river.

The control cable is a PVC insulated and PVC sheathed control cable suitable for use in industrial and mining enterprises, energy and transportation departments, and for control and protection circuits with AC rated voltages below 450/750 volts.

The following editor will show you how to distinguish between power cables and control cables.

1. The different implementation standards of power cables and control cables:

Standard of control cable: 9330; Standard of power cable: GB12706;

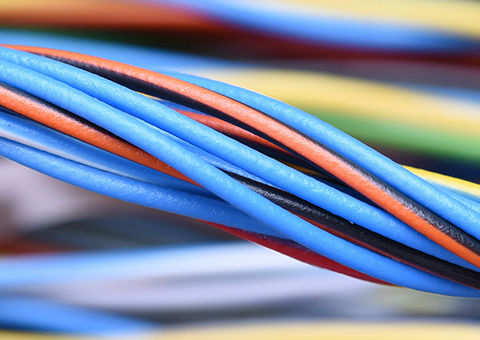

2. The core colors of power cables and control cables are different:

The color of the insulated core of the control cable is generally black and white, and the low voltage of the power cable is generally color-separated.

3. Power cables and control cables have different functions:

Control cables directly transmit electrical energy from the power distribution point of the power system to the power connection lines of various electrical equipment and appliances. Power cables are mainly used for the transmission of strong electrical energy in the power generation, distribution, transmission, transformation, and power supply lines. With large current, power cables are used to transmit and distribute large-function electrical energy in the backbone of the power system.

4. The size of the power cable and the control cable section are different:

The power cable is a primary load wire, and the current carrying capacity increases with the increase of power. The application cross-section of the wire must also increase with the increase of current. Therefore, the size of the power cable is generally larger, up to 500 square meters (conventional manufacturers can produce Scope), no matter how large the cross-section is, there are relatively few manufacturers that can do it. The control cable is a secondary command wire, which controls the current-carrying operation of contactors and other devices. The load current is extremely small, and the wire section is extremely small, so The cross-section of the control cable is generally small, and the maximum generally does not exceed 10 square meters.

5. The number of cores of power cable and control cable is different:

The number of cores of power cables is small, including single core, two cores, 3 cores, 4 cores (three-phase four-wire system), and 5-core (three-phase five-wire system). According to the requirements of the power grid, the maximum is generally 5 cores. The control cable is used to transmit control signals, with more cores, ranging from 2 cores to 61 cores, or even more. The control cable also adopts various core structures, shielding and other measures to obtain satisfactory electromagnetic compatibility effects.

6. The rated voltages of power cables and control cables are different:

The rated voltage of the power cable is generally 0.6/1kV and above, and the control cable is mainly 450/750V.

7. The wire skins of power cables and control cables are different:

Power cables require that the wire sheath has sufficient compressive strength, tensile strength, temperature resistance, and corrosion resistance. The control cable requirements are relatively low. When industrial electrical power cables and control cables of the same specification are produced, the thickness of the insulation and sheath of the power cables is thicker than that of the control cables.